Greenboats make a sustainable splash at METSTRADE 2019

The word ‘pioneer’ is quite often used in these days of rapid technological innovation, but Friedrich Deimann of Greenboats is one of those quietly determined, hard working heroes, who it’s easy to apply the description to, when it comes to the future of sustainable boat building.

At METSTRADE 2019, as part of the sustainability program at the I-nnovationLab stage, Friedrich presented the innovative and futuristic construction material ideas that he has incorporated into his Flax 27 Daysailer, the most complete natural fibre composite project that he has produced so far, after 10 years of diligent research and development. Even a boat with outstanding sustainability credentials has to be attractive to look at, and fun to sail, if you want people to buy it; so, Friedrich chose a sleek 8.2m classically styled sailing sloop, from the boards of renowned naval architects Judel/Vrolijk as the basis for his environmentally friendly creation.

From tradition to green innovation

Friedrich told his story from the beginning; how he had gone sailing with his uncle as a young boy, and developed a fascination about how to build boats, and to learn about the materials of construction employed. At age 18 he started working as a boat builder apprentice, with a company producing wooden sailing boats from traditional materials such as mahogany. Although this was rewarding work, with every boat completed being like a ‘piece of art,’ Friedrich quickly realised that the future was not in wooden boats, due to the high costs of ownership and maintenance.

After completing his apprenticeship, he went on to work with a specialist composites producer which soon convinced him of the benefits of composite construction, being lightweight, strong and easy to mould into free-form shapes. But, as anyone who has worked in a fiberglass lay-up shop will know, polyester resins and glass fiber strands are not user-friendly materials, causing irritation to the skin and emitting unpleasant toxic fumes. “Not much fun to work with,” said Friedrich!

So, after four years he moved on to study for a Masters in boat building, during which time he thought long and hard, about how to incorporate materials from the natural world into the obvious structural advantages of composites. And, looking for alternatives to glass strand reinforcement he came across flax fiber, which is about half the weight of glass fiber, ends up just as strong, and lends itself well to vacuum infusion type production methods. Not only is it less harmful to health and more pleasant to work with says Friedrich, but overall, it’s better for the environment, as it consumes 5 times less energy to produce than GRP, and 20 times less than carbon fiber, due the fact that it grows naturally in fields.

A bio based resin matrix

The next job was to find a reliable resin system that was not petro-chemical based, a task which involved lots of research into various alternatives and practical testing to establish the best option. Bearing in mind that this journey started nine years ago, when bio resin technology was in early development. Eventually Friedrich settled on a partnership with bio epoxy provider Sicomin, and the hull, deck and internal structure of the vessel were infused with their very low viscosity GreenPoxy InfuGreen 810 resin and reinforced with the flax fibre fabrics. During the Greenboats testing program, carried out in conjunction with the University of Bremen, they had ruled out a 100% bio based resin as it would not provide sufficient long-lasting strength. So, the chosen resin is 31% bio based, and still uses a petrochemical based hardener.

A sample of the exact material used for the daysailer, incorporating the flax and the bio epoxy resin was independently tested for its mechanical properties, where it withstood a deflection force of 20,000 newtons, which compares very favorably with a glass fiber composite. In fact, scientific evidence suggests that natural fibrous materials used in resin lay-up reinforcement can exhibit better characteristics than glass fiber in terms of density, deformation and load bearing performance. By working with Judel / Vrolijk’s designers and incorporating the test data results from the selected materials, Greenboats managed to produce the Flax 27 with a total weight of 1200kg, saving about 70kg as compared to building the same boat from glass fiber.

Eco friendly core materials

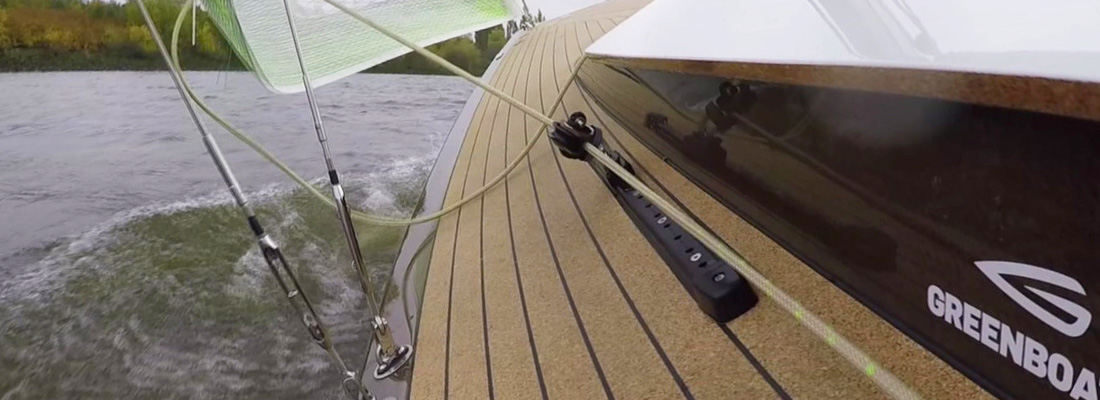

In a boat that is claimed to be 80% built from sustainable materials, Friedrich has also made the use of recycled substances, such as PET (plastic bottles) for the sandwich construction, and cork which he says he found to be much more suitable for marine use than some people might think. He is even using it for the decks, because it is much lighter than teak, has good anti-slip, insulation and vibration suppression properties, its hydrophobic, so doesn’t absorb water, and even self-repairs to some extent if slightly damaged.

Awards and more development

The Greenboats pioneering approach towards more sustainable boat building has certainly got some attention, winning several technology accolades along the way including the Ocean Tribute Award supported by the Prince Albert of Monaco Foundation. Friedrich is happy to share his expertise and experience too, cooperating with other manufacturers to produce city benches, foiling kite boards, and several other items made from similar natural fiber reinforced composites.

The entire presentation by Friedrich Deimann was video recorded and you can check it our here:

Share your stories on leisure marine industry with us

Do you have an innovation, research results or an other interesting topic you would like to share with the leisure marine equipment industry? The METSTRADE website and social media channels are a great platform to showcase your stories! Let us know via metstrade@rai.nl

Are you a METSTRADE exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

.jpg?h=400&iar=0&w=1200)