Exploring natural alternatives, recycled materials, or renewable resources for yacht construction could lead to a more substantial reduction in the environmental impact of yachts compared to simply reducing fuel usage. While builders of small and mid-sized yachts are pioneering, the superyacht sector welcomes availability of sustainable finishing materials.

by Hans Buitelaar

The use of materials and the whole process of constructing yachts is causing a very significant chunk of the whole environmental impact a yacht poses throughout its lifetime. The first life cycle assessments that research and calculate the overall impact on the natural environment as caused by pleasure boats, indicate that not so much the use of fuels is the largest source of pollution caused by boats, but the use of non-recyclable materials. If the yachting sector really wants to evolve into a net zero industry, the use of materials needs to be addressed.

User profiles

This has to do with the quite low overall use of boats, that typically float in their berths about 300 days a year and are only used the other 60 or so days every year. With commercial ships or even cars, the balance is totally different as their engines are running continuously (for ships) or several hours every day (for cars). With large yachts, the balance is again slightly different. There, the air conditioning is constantly running, being the largest energy consumer on board. Engine use for propulsion is only a small part of the overall energy use on board. With lots of attention for renewable fuels, electrification of the propulsion and better design of the overall use of energy on board, also for the hotel functions, the shift from fossil to cleaner fuels has found its way into the yachting industry. The ecological footprint of construction materials is only starting to become a focus point in yacht building.

Available

Smaller and mid-size yachts seem to be ahead of super yachts in aspects of applying new construction materials. Yet, attention for materials used in the interior, finished and non-structural parts aboard large yachts is increasing. In a market that is highly customised, sustainable materials are among the many choices an owner has for assembling his required yacht.

Wood based composites

The shift from fossil to renewable is gaining momentum in yacht building. One very obvious option is to restart using wood as a construction material for yacht hulls. The UK-based company Spirit Yachts does this, applying modern construction techniques, creating a composite with wood as the most voluminous material, bonded by modern glues and resins like epoxy or even bio-based epoxies. The yard offers sailing yachts from 30 feet up to 111 feet, racing sailing yachts in a classic design, power yachts from 35 overall length up to 70 feet, including the electric propelled and foiling 35 E.F.. This is a clear manifestation showing that wooden built yachts can be lightweight. Weight and maintenance have been important factors that have triggered the shift from traditional wooden yacht building towards fibre glass boat building in the 1950s and ‘60s. Creating the wood based composites, strengthening them with synthetic materials like carbon fibre and epoxy, modern day wooden boats can be built lighter while still being strong enough and they are well preserved. Various species of wood are used. The yard expresses its commitment to using renewable material sources and clarifies that wood will grow again, while trees take up carbon dioxide as they grow.

3D curved wood panels

In the Netherlands, boatbuilder Roelof van de Werff and aeronautical engineer Henk Bergsma joined forces to develop a new way of building boats, using three dimensional curved wooden panels for the hull. Their motor yacht Werffboat 24 is computer designed.

The hull design with specific curvature is sent to Curveworks, a company that produces three dimensional curved panels in composite but also in wood. The duo then glues the pre-shaped panels for their hulls to the mock-up of frames that they have set up in the workshop. This way, they can build lighter boats in wood that are strong and well preserved. In the process of creating two-way bent wooden panels, sheets of veneer are glued together with epoxy.

At the Curveworks workshop, the panels are laid over an adaptable mould. This mould consists of vertical actuators, that slide up or down to exactly recreate the required curvature to fit the hull design. The package of veneer sheets is laid over the adaptable mould well within the pot life of the glue and then cured while being held over the mould with the set curvature through a vacuum.

Back at the yard for Werffboats, the panels are placed on the hull. For larger yachts, two or more layers of panels overlap to eliminate the problem of seams in the hull skin. For smaller boats, a strip of the curved panel is sown off, to form a connecting strip that is glued to the inside of the hull to close the seam. Van der Werff and Bergsma work with bamboo and cured pine wood, a durable timber with the trade name Accoya.

Oak bark

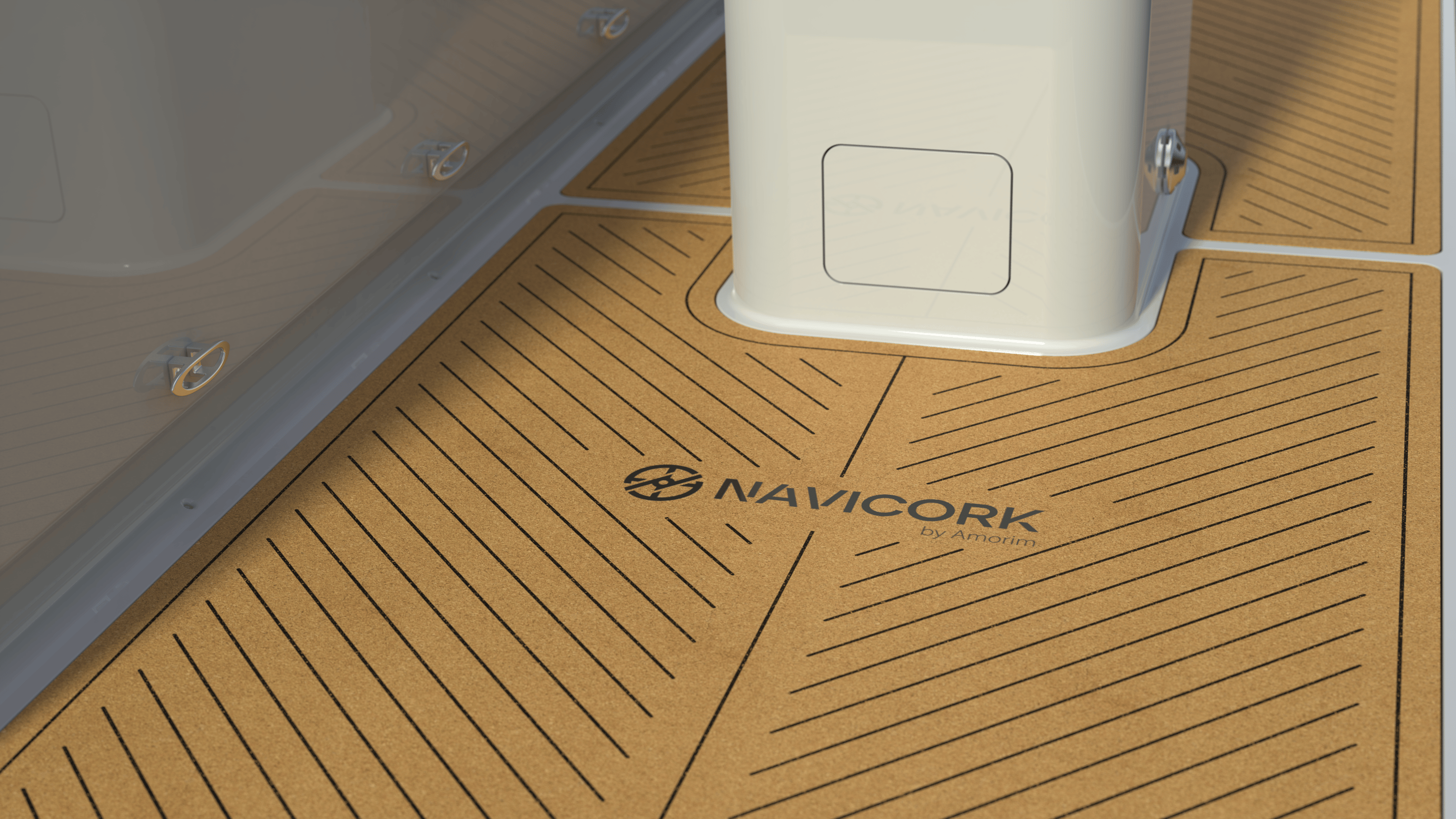

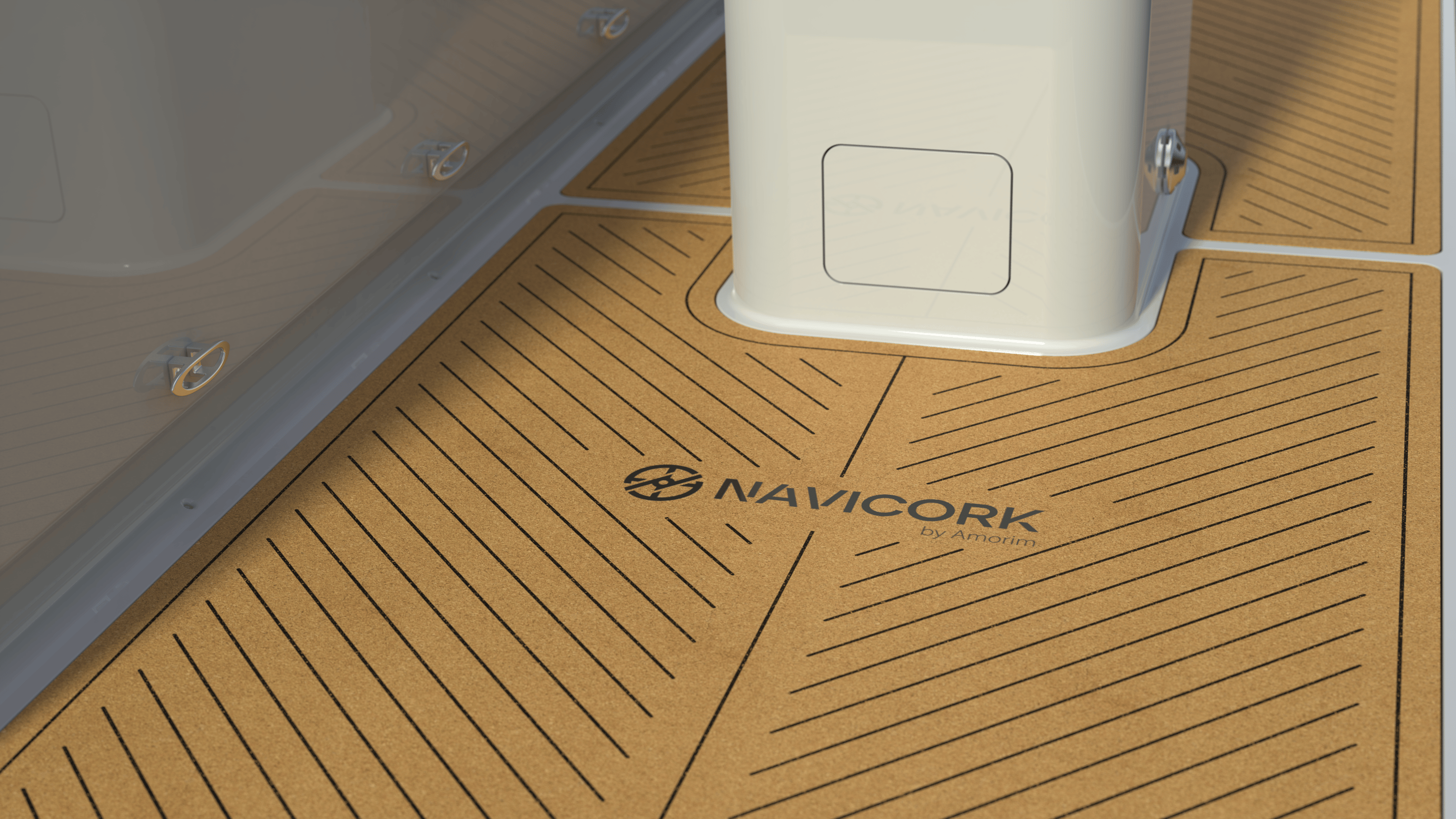

“Cork is actually CO2 negative,” Udo Kleinitz explains. “During the time it grew, this cork oak bark captures a lot of carbon from the atmosphere. Our third-party verified data confirms one ton of cork absorbs up to 73 tons of CO2. To produce cork, only the bark is harvested and the tree remains regrowing the bark for a next harvest cycle of nine years or so. The cork oak forests in Portugal and other places around the Western Mediterranean basin are recognised by UNESCO as one of the 36 most important biodiversity hotspots in the world.” Kleinitz is business developer for Navicork, a new company of cork decking solutions for large yachts. He emphasises the favourable properties of cork. The material has excellent insulating properties, it feels pleasant under bare feet and it has excellent anti slip properties. Because of the insulating quality, the surface stays cool, but a cork deck also reduces the heat below decks, allowing for energy reduction for the air conditioning. “Cork is high performance and more sustainable material as compared to traditional teak plank decking. Using cork, we can create a deck with the same traditional planking pattern as with teak, but we can do all sorts of different styling and patterns. This makes it also a very suitable decking surface for contemporary yachts that do not aspire traditional stying.” While cork as a decking material has been used since the 1980s, mostly on smaller or mid-sized yachts, Navicork aims to demonstrate the superior quality of the material and the product made out of it, to convince superyacht owners and yards to apply it.

Basalt

Kleinitz is one of the speakers at the panel discussion ‘New Materials in Boat Building’ held at Düsseldorf Boat Show. He is joined by business developer Guillaume De Jonghe of Basaltex and Marion Koch of Innovation Yachts. Basaltex produces fabrics and rovings from the natural rock basalt and presents these bonding layers for composites as a sustainable alternative for glass fibre or carbon fibre for the yacht building industry. Innovation Yachts is one of the first yards to use the ‘volcanic rock fibers’ in their yachts. Together with bio-based recyclable epoxy, they claim to build fully recyclable composite yachts, from 16 foot up to 60 foot. The epoxy resin can be separated from the fibres after the boats lifetime, for both the resin and the fabric to be used again.

Recycled

While the initial production of aluminium from bauxite requires a significant amount of energy, the recycled material can be reused with relatively low energy consumption. This inspired Igor Kluin to start his brand of environmentally conscious sailing catamarans Vaan Yachts. The hulls, deck and deckhouse of these 40, 50 and 60 foot cabin catamarans are built (as much as available) out of recycled aluminium. To further express the sustainable nature of the yachts, Kluin researched all kinds of new natural materials to finish his yachts. The fabric of the cushions aboard is made out of palm leaves. Furniture is built from certified sustainably grown timber, the decks are fitted with cork. Founder Kluin of Vaan Yachts would like to see a sustainability advisory board for the yacht building sector, he tells the Dutch yacht building association HISWA: “The industry is now shifting towards sustainable boat building. In this process, small new solutions that actually contribute little to solving the environmental footprint of a yacht, are heralded as breakthrough innovations. This is part of the process. Still, to ensure that the transition will deliver true results, it is necessary to assess what materials, building methods and technologies really contribute to sustainable yachting.”

Hans Buitelaar

Hans Buitelaar