Kim Hollamby

Kim Hollamby

As the recreational marine sector gathers momentum to meet net zero objectives, which environmental initiatives are gaining traction and what sustainable developments can we expect to see progress on at METSTRADE 2024?

The critically important push towards net zero and elimination of ocean pollutants are primary examples of how extraordinarily tough targets are hard to visualise, let alone achieve, if contemplated in their entirety. Taken as headline objectives, they seem like implausibly steep mountains to climb unlesachievable steps are identified.

In years ahead it is highly likely that better developed technologies, materials, processes, and energy sources will benefit the recreational marine sector’s transformational objectives. Meanwhile, there is welcome evidence of tangible efforts to establish a strong environmental basecamp with what is available today.

In this article we look at five sustainability enablers that are reducing environmental impacts now. Plus, we predict four further areas of development to look out for.

The development of effective onboard energy storage is vital to enable pure electric or hybrid propulsion and to reduce dependence on fossil fuel to deliver ever-increasing hotel electrical loads.

Lithium-ion batteries have become the dominant technology for this task, despite reservations over safety. Enhanced battery management systems have developed to address the safety issue and guard against thermal runaway while playing a bigger role onboard with additional environmental benefits. Taking two recent examples:

The environmental burden of mining the rare raw materials required for new manufacture of lithium-ion cells and lack of obvious recycling solutions have raised environmental questions. In recent times though we’ve seen answers emerging with major organisations such as Stena Recycling opening reprocessing facilities to create ‘black mass’ (a mixture of valuable metals such as lithium, manganese, cobalt, and nickel) for use in new cells.

The marine industry is poised to move into alternate battery technologies. Solid state batteries made their first appearance at last year’s METSTRADE and these have much more robust safety characteristics over conventional lithium-ion.

Alternative chemistries using more common materials are also in the wings. The latest generations of sodium ion batteries offer improving energy density performance over earlier versions. Key markets remain landside energy storage, but it seems likely this solution will find its way onto some boats before too long. Recent breakthrough research on aqueous batteries (that utilise water-based electrolytes) hints at the potential for this technology also.

A walk around this year’s Construction Material Pavilion (CMP) is certain to unveil latest developments in the field of sustainable composites, timbers, and fabrics.

Deck finishes is an obvious place to start, given the impossibility now in many leading boatbuilding states of securing legal teak supply. The options are far ranging, from alternate hardwoods and pressure-treated softwoods, to cork, plastic-based simulated teak and carpet-based materials. It seems likely there won’t be a universal winner in the race to replace teak, but instead builders and refitters have choices that can be made according to budget, customer preference and intended service use.

There is steady progress in composites with the emergence of bio resins and alternative reinforcement materials such as organic fibres and basalt, reducing manufacturing power consumption versus traditional glass. Attention is also being paid to more easily recyclable core materials.

Alongside this we’re seeing commercially viable fibre reinforced plastic recycling options swinging into first level production, such as that pioneered by Swiss company Composite Recycling and highlighted in Beneteau’s Sustainability Project of the Year win in last year’s IBI METSTRADE Boat Builder Awards. The output from projects such as this is becoming available at first in the form of partially recycled GRP. There are similar pioneering projects underway for carbon fibre, including one run by the Carbon Fibre Circular Alliance of which the World Sailing Trust is a partner.

Additive manufacturing is another fast-moving area within the METSTRADE CMP. 3D printing is a perfect technology for the relatively low production volumes of the marine industry. It saves energy and materials by moving straight from computer to final manufacturing and is a proven user of recycled plastics. The most likely applications will be in the area of component manufacturer but we are now seeing full production additive manufactured boats too such as the Dutch IMPACD Boats range where the design can be adjusted easily and economically for local market factors.

Mention sustainable propulsion and you naturally think electric motors now. There has been an explosion of exhibited products in this segment at METSTRADE in recent times, highlighted by the launch of last year’s Next Generation Propulsion Zone and announcement of the 2023 DAME Design Awards overall winner – Oceanvolt’s HighPower ServoProp 25.

Just providing a motor to propel a boat is not the end of the story though. Next stage developments in pure electric and hybrid propulsion will surely focus on improving efficiency and management. That in turn will also be reliant on key components such as propellers where specific models are being optimised to match the power delivery characteristics of electric motors.

The way we deliver power may also turn out to be completely different in the future, as Hans Buitelaar’s recent article on biomimicry explains. The growing science of foiling offers significant drag reduction and applications are edging closer to mainstream, as highlighted in the Foiling Technology Pavilion. However, neither is likely to make as much impact in the short term as finding solutions for the existing global recreational craft fleet of 30m boats.

ICOMIA’s Pathways to Propulsion Decarbonisation for the Recreational Marine Industry research report, launched at last year’s METSTRADE, scientifically demonstrates that the role of the internal combustion (IC) engine is far from finished. Hence continued development with spark and compression ignition engines and outboards remains likely, building on impressive efficiencies achieved over the past two decades.

One way of reducing carbon and resources impacts in equipment manufacturing is to design products to last longer. That means moving away from a throwaway approach to one where easy servicing and even upgrading is supported. ICOMIA research suggests that many boats are exceeding 50 years of service. Another area of focus should be to ensure those boats can be refitted more easily.

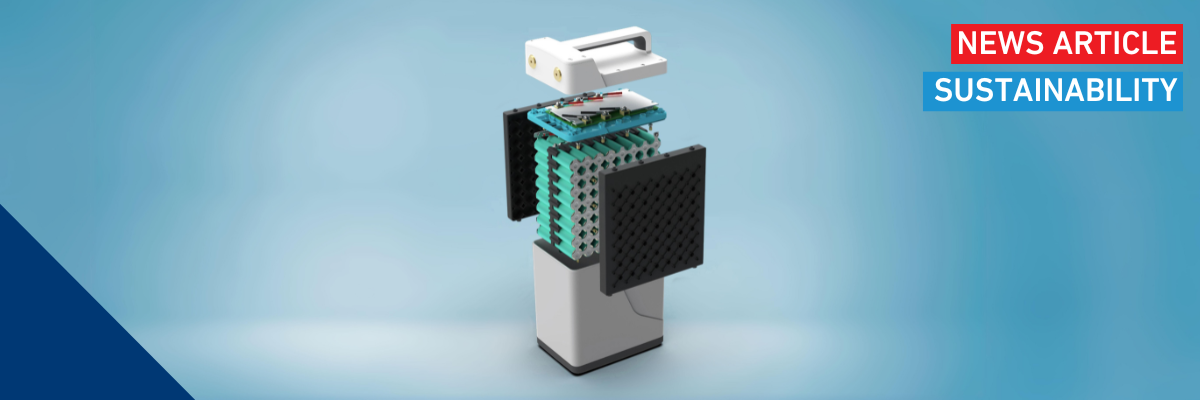

The industry appears to be moving towards greater serviceability of its products, commonising parts and reducing the use of unsustainable materials, albeit at a pace dictated by the frequency of new model introductions. A case in point is OceanLED’s Explore E8 and E9 underwater lights which were among the first products anywhere to attain listing on the Water Revolution Foundation’s Database of Sustainable Solutions. Another great example is Aceleron (pictured in our header) which won the 2022 DAME Design Award for Environmental Design for its modular Essential lithium-ion battery – this enables individual faulty components to be swapped out for new ones rather than scrapping the whole battery.

One of the first environmental priorities that most marine companies tackled is reducing the impact of their operations. There are many obvious areas for improvement, such as waste management, power generation, water and power consumption reduction, elimination of single plastic use, a change from paper-based to digital materials and many more. How far and fast businesses have been able to push will have depended in part on their trading health and on the grant support available from regional and national governments.

Desire to change is another factor. Some notable marine companies have empowered employee groups within their organisations to drive their corporate environmental agendas. This has brought real passion to making change happen and helped those businesses retain loyal and engaged employees.

Many METSTRADE exhibitors are now moving to eco-packaging solutions. This is not always an easy pathway, in some cases moving once automated processes back to manual ones. However can expect to see further improvements in this area as a greater range of sustainable materials becomes available.

Another emerging trend is for the policies of buyers to dictate sustainability requirements to supply chain partners. At a basic level this might involve insisting on no single use plastics in consignment packaging. For the future there is a growing feeling that independent environmental certification will become more commonplace to achieve authenticity in the claims made for end manufactured products and boats.